Hydrogen Sulfide, and Sludge Reduction – Chicken Processing Plant

Biologically Active Carbon

Problem

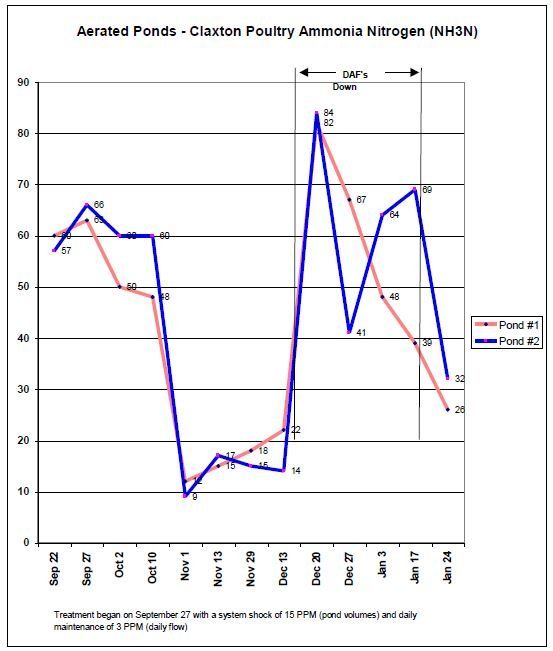

A large chicken processing and rendering plant in Southeast Georgia was faced with numerous problems associated with the treatment of waste water at the plant. The plant has a daily flow of 1.8 million gallons of water. The first problem was a heavy fats, grease and oil build up on the surface of a 10,000 gallon grease trap located down-line from the rendering building. The solids build up on the surface of this grease pit would exceed 2.5 feet and forced the plant operators to physically remove the cap with a backhoe once the thickness of cap began to reach the overflow level of the pit. The second problem was high TSS (750-1100 ppm), COD/BOD (1400-1800 ppm), and ammonia nitrogen (50-70 ppm) levels in the plants two aeration ponds. These ponds are in sequence with the first pond having a capacity of 4.5 million gallons and the second having a capacity of 14 million gallons. The plant has a land application permits which allows for irrigation of hay fields with the treated wastewater. The third problem resulted with high H2S levels being generated by the aeration ponds.

Solution

To address the sludge cap problem on the grease pit Histosol OP-GRZBio 20 was applied through a pressure sprayer at a rate of 8-ounces per gallon directly onto the surface of the cap. One quart of concentrated product was applied per treatment. The cap was treated twice each day. Within 7 days the cap was reduced to approximately 5 inches of tan foam. Treatment continues at the same rate twice daily.

To address to TSS, COD/BOD, ammonia nitrogen, and hydrogen sulfide problems in the aerated ponds Histosol OP-Bio 10V was the recommended product. Pond #1 (4.5 million gallon capacity) was shocked with 75 gallons (17 ppm) and Pond #2 (14 million gallon capacity) was shocked with 175 gallons (12 ppm). The shock treatment was applied with a high pressure hose to provide a more uniform coverage of the pond surface area and allow for better blending of the product into the wastewater. A daily maintenance program was implemented where 5-gallons (2.8 ppm of the daily flow rate) of product would be metered into pone #1 at the influent point.

There was a significant reduction in hydrogen sulfide odors with 48 hours of treatment. After 30 days of treatment the TSS and COD/BOD levels on average were reduced by 60-65%. The ammonia nitrogen levels were reduced by approximately 85%. (See charts on following pages). The maintenance application rate of 5 gallons per day continues.

Condemned Pounds of Harvested Product (Chart #3)

The Histosol products used in this application far exceeded original expectations.